Nanoparticle structuring

Our research group focuses on the development of scalable manufacturing processes to structure nanoparticles into well controlled hierarchical structures. For this, we study the interactions between the nanoparticles and methods to influence how they aggregate into superstructures using combinations of top-down lithography and bottom-up self-assembly. We mainly use carbon nanoparticles as a structural backbone as well as to provide electron transport and hybridise them with a variety of inorganic nanoparticles to achieve new functionalities. By combining unique control over material geometry at the microscale and control over interfaces and material chemistry at the nanoscale we are able to rationally design advanced material architectures for energy storage, water filtration and sensor applications.

Carbon Nanotubes (CNTs)

CNTs are seamless cylinders of one or more layers of graphene (denoted single-wall or multiwall CNTs respectively). CNTs are particularly attractive as a backbone material for our research because some of their properties are unlike any other engineering material (e.g. tensile strength of 100 GPa, elastic modulus approaching 1 TPa). In addition, the synthesis of these materials is well established as is best understood by the production volumes shown in the inset image. More information on this topic can be found in following review papers on carbon nanotubes applications.

![(Top) Evolution of the production capacity of CNTs over the past years, along with numbers of yearly publications and patents. (Bottom) CNT application Milestones [De Volder et al, Science, 2013]](https://www.nanomanufacturing.eng.cam.ac.uk/files/styles/large/public/media/Fig1Final.jpg?itok=Y4xDw56H)

Elasto-Capillary Aggregation

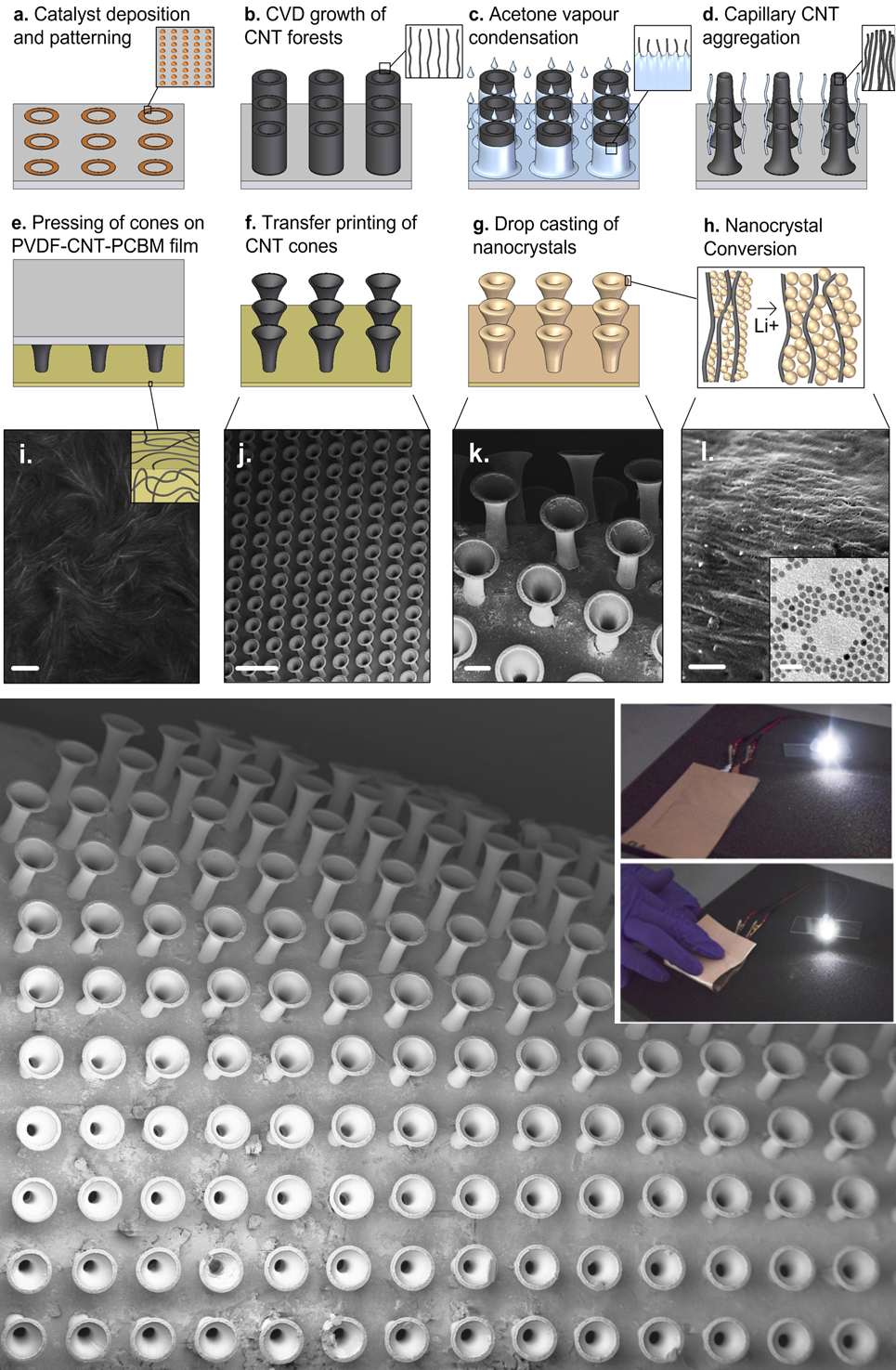

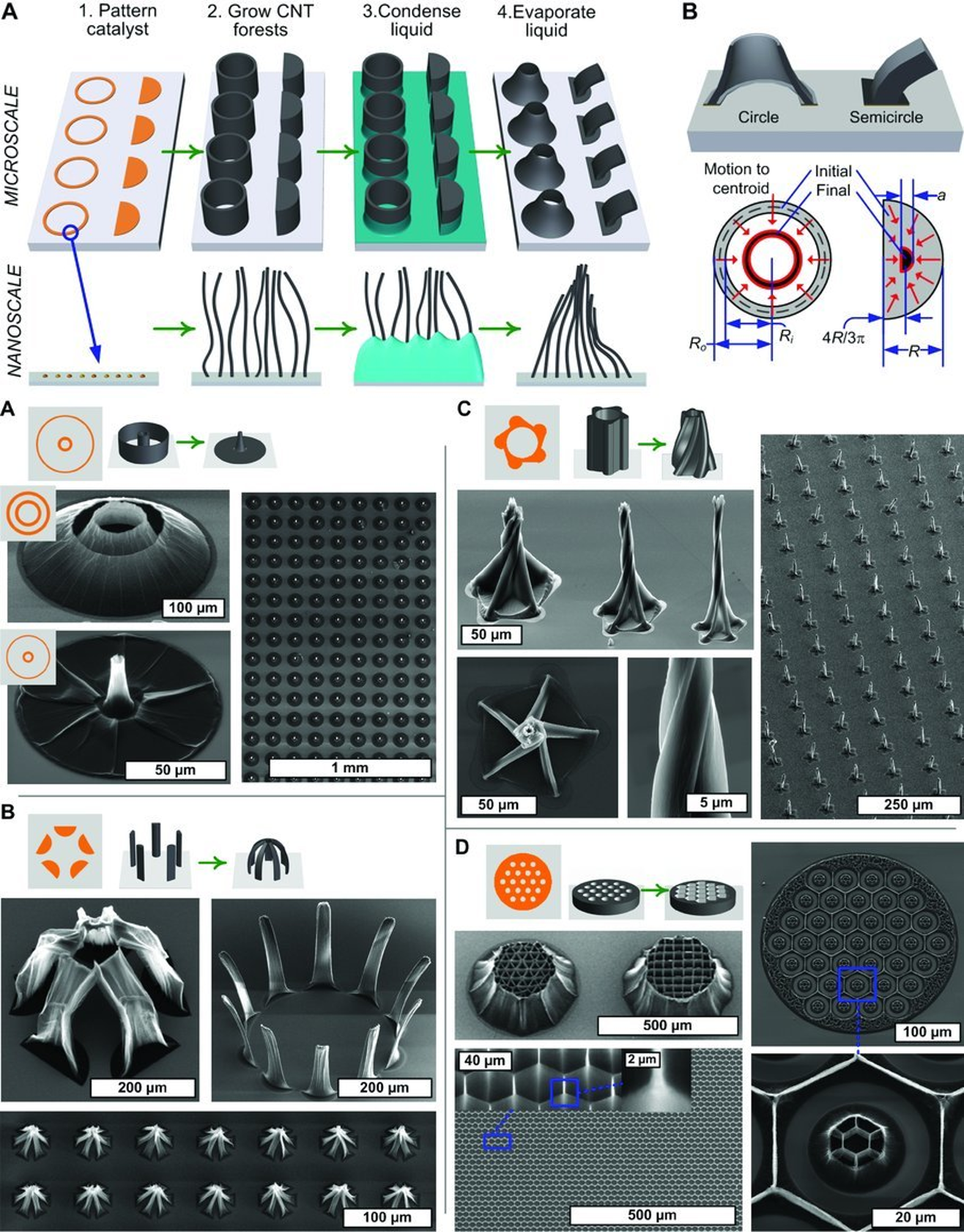

Importantly, the exceptional properties of CNTs discussed above are typically measured in individualized high quality nanoparticles. Many engineering applications of these materials on the other hand require tens to millions of nanoparticles to be assembled into one device, and unfortunately, to date, the properties of such nanoparticle assemblies are often disappointing. We are therefore conducting more research in advanced assemblies of these particles. This includes in particular methods to align CNTs and to organise them into well controlled 3D geometries. The nanoscale alignment of CNTs is important for the performance of the CNT devices and their 3D organisation is key to create new devices and to unlock new nanomaterial based applications. Our CNT structuring methods are starting from a Chemical Vapour Deposition (CVD) technique resulting in aligned CNT 'forests', which are patterned using ligthography and are then transformed in 3D structures geometries using capillary aggregation methods depicted in the scheme below. This process was developed in collaboration with Prof A.J. HArt at MIT and S. Tawfick at UIUC (more information about the process can be found here).

Strain-Engineering of CNT Structures

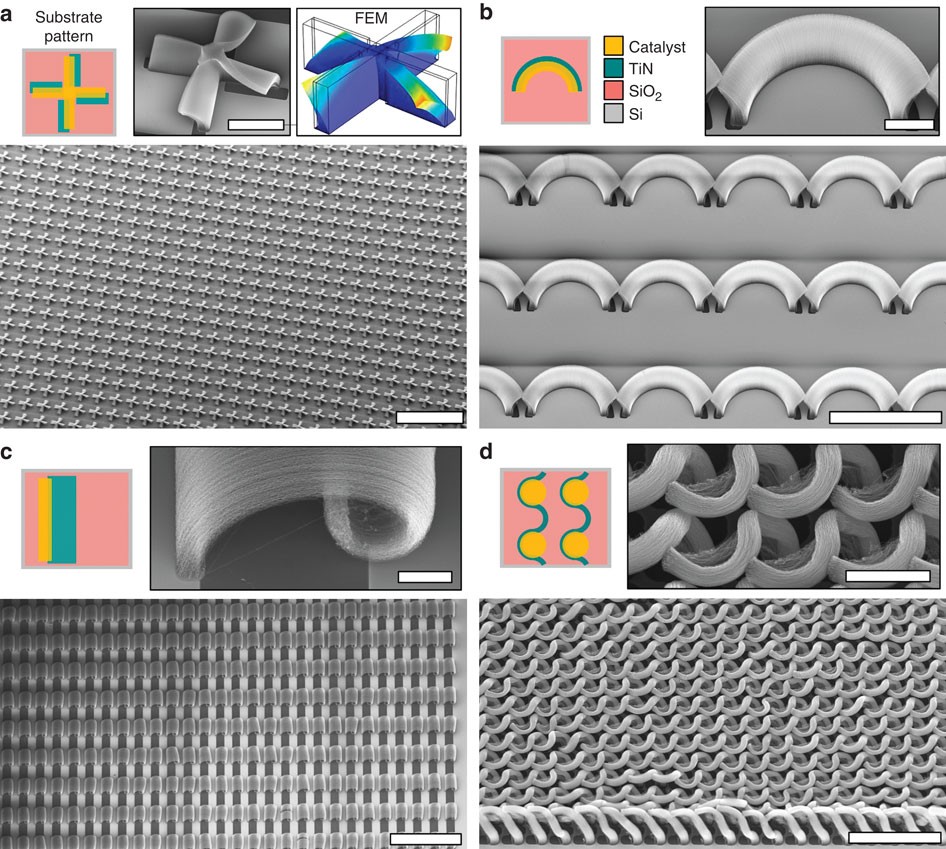

Alternatively, we have developed a process where differences in CNT synthesis rate depending on the catalyst and catalyst support material are used to modulate stresses in CNT materials to create 3D CNT geometries. In our work we used lithographic processes to pattern TiN, Si3N4 and SiO2 catalyst support layers and have patterned CNT catalyst layers bridge different catalyst supports as depicted in the image below. This allows for the fabrication of large arrays of 3D CNT structures with high yield. More details on this process can be found here.

Applications

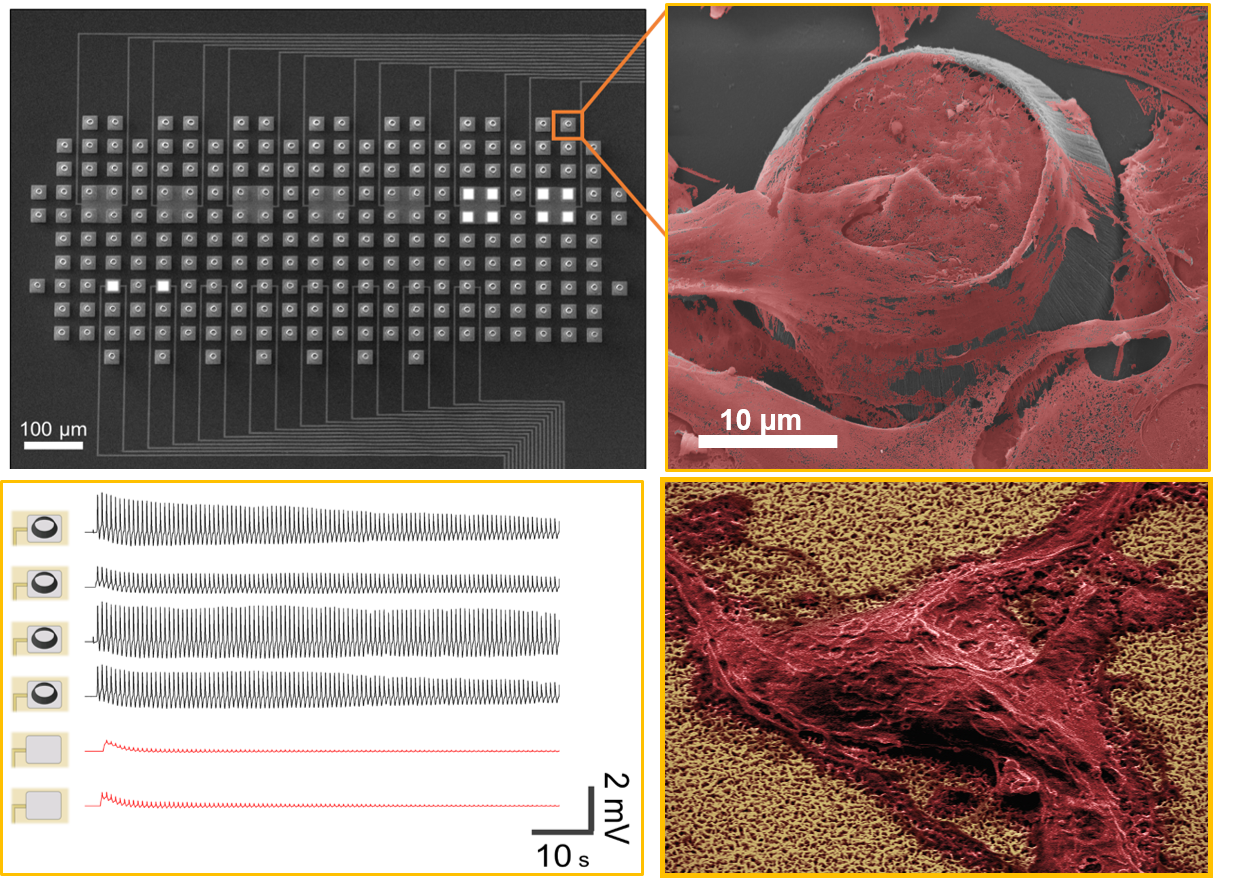

Control over the 3D architecture of CNTs allows to design their morphology to suit different applications such as sensors and actuators (more information can be found here) or for bio-interfaces. For instance, the images below show arrays of CNT cones whose dimensions match those of electrogenic cells and allows to extract richer electric data than standard reference electrodes located in the same device. More information about these devices can be found here.

Controlling CNT architectures allows for fabricating Li-Ion batteries with new properties, including improved flexibility. The flexible batteries that are needed to power flexible circuits and displays remain challenging, despite considerable progress in the fabrication of such devices. We have developed flexible batteries using arrays of carbon nanotube microstructures, which decouple stress from the energy‐storage material. For this application, the 3D CNT architectures discussed above are transfer printed onto collector electrodes (Cu or Al foils) and are coated with active battery materials (Fe2O3 anodes and LNCO cathodes). We tested these batteries in half and full cells and found that our proposed battery architecture imparts exceptional flexibility (radius ≈ 300 μm), high rate (20 A g−1), and good cycling stability. More information about these devices can be found here.